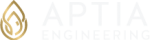

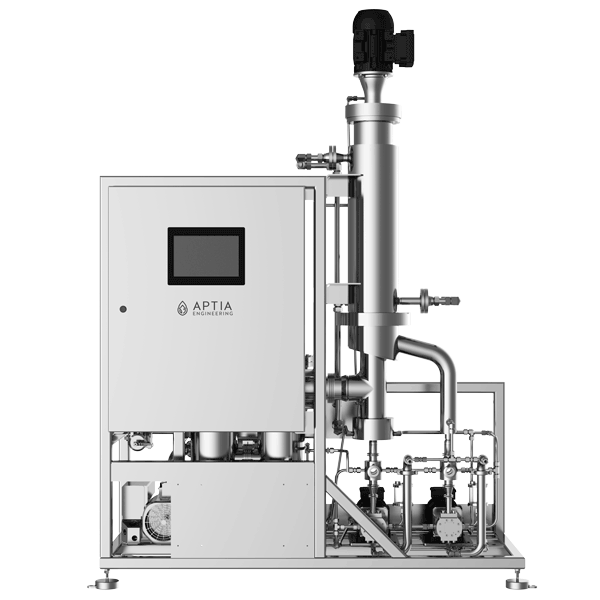

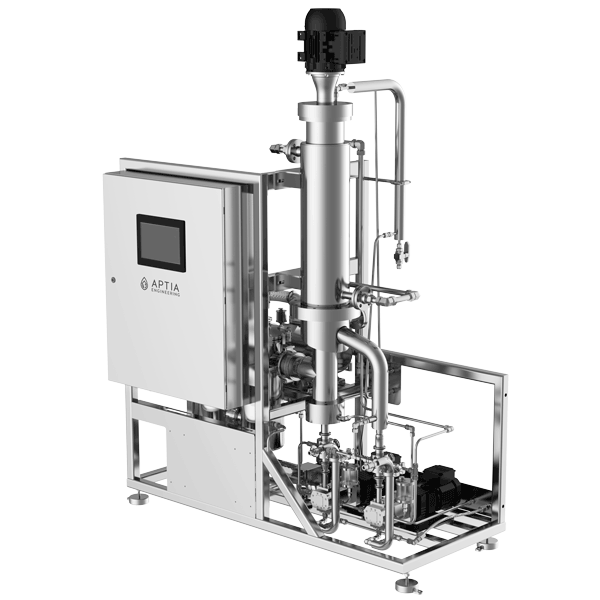

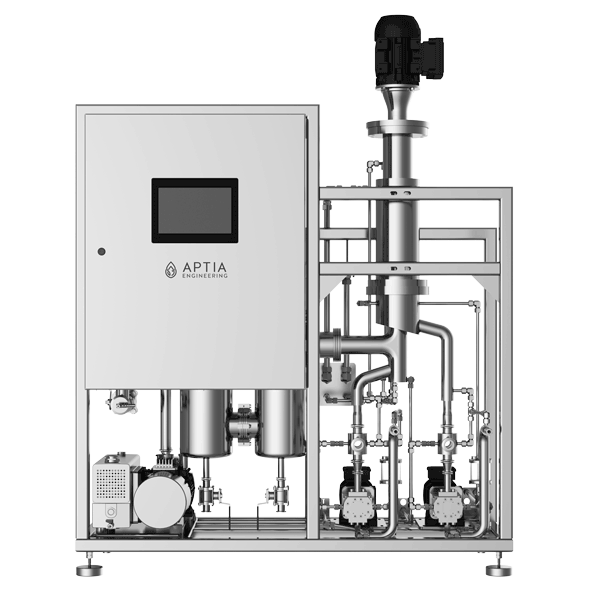

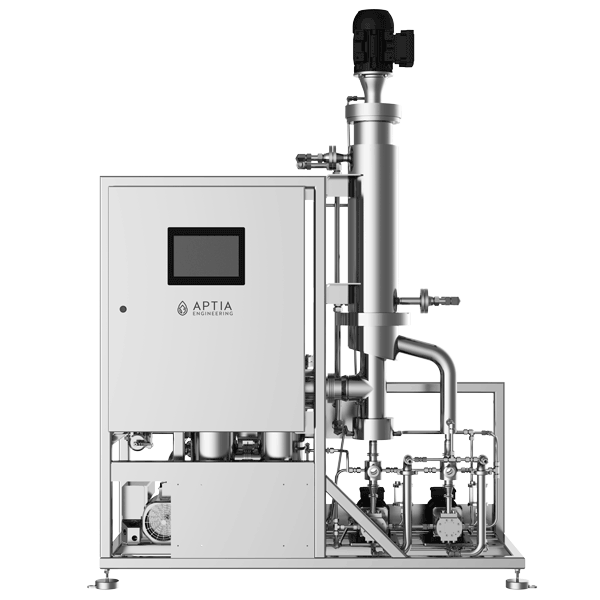

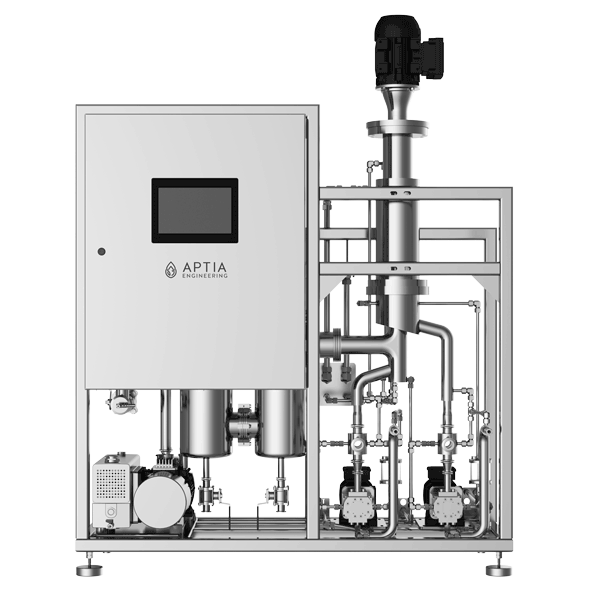

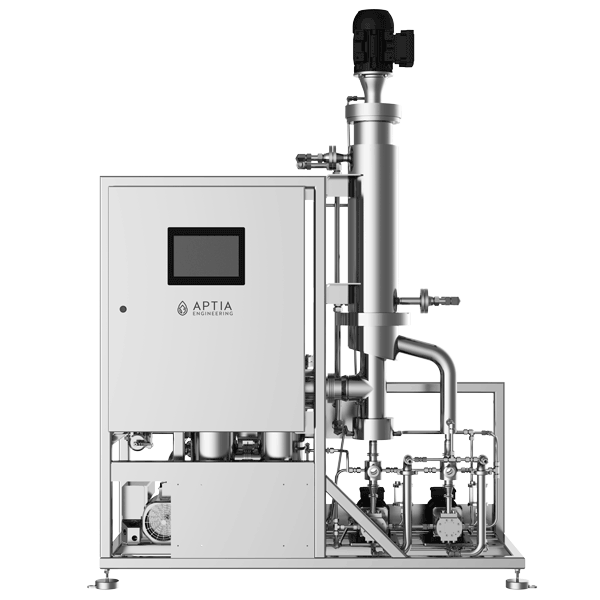

WFD-V Series

Wiped Film / Thin Film Short Path Distillation Systems

The WFD-V systems are precision-engineered, thin film, high-vacuum, molecular distillation systems specially designed for the rigorous demands of the botanical extraction industry.

Available Models

Applications

One Year Warranty

Installation and Training Support

Engineered & Built in the USA

Product Description

Inspired by years of experience engineering systems for the botanical extraction industry, the WFD-V Wiped Film Distillation systems are intuitive to operate and robustly manufactured.

The WFD-V is available in two standard sizes based on the evaporation surface area: 0.12m2 (WFD-V12) and 0.36m2 (WFD-V36). Larger systems can be manufactured as needed by Aptia’s in-house engineering team.

All thin film systems are manufactured from the highest quality materials, equipped with premium gear pumps and instrumentation, a novel 2-stage high performance cold trap, and touchscreen controls. The WFD-V systems include modular feed skids which ensure consistent batch-to-batch processing. Innovative features, combined with the highest quality, precision engineered components result in unparalleled performance and reliability at an unbelievable value.

Features

- Precision-Engineered, USA-Fabricated Thin Film Evaporator

- Configurable, Modular Feed Skid Options

- Touchscreen PLC

- Wiped or Rolled Film Agitators

- Two-Stage Cold Trap

- Heated Gear Pumps

- High Performance Vacuum Package

- Heat-Jacketed Plumbing

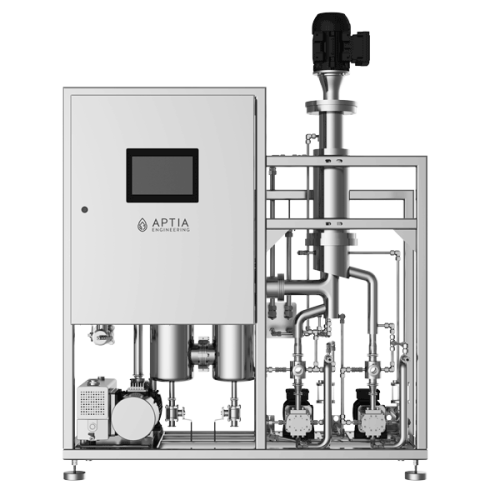

Pre-Condition Extract With the Configurable Feed Skid

Aptia’s WFD-V platforms come with configurable feed skids. The feed skids include vacuum rated, jacketed, and agitated reactors that pre-condition the extract to provide greater throughput and better product consistency.

Pairing a feed skid with your Wiped Film unit promotes higher throughput and product consistency by conditioning and homogenizing extract prior to distillation. The feed skid reactor can be used to decarb, degas and homogenize the extract that is then fed into the distillation system.

The feed skid can also be configured to condense and collect the volatile gasses, including terpenes, that are released during the decarboxylation and degassing process.

Aptia offers numerous feed skid options in order to provide the best configuration for each installation.

PLC Touchscreen Interface

Smart and intuitive process control is achieved by utilizing a touchscreen PLC which provides operators with instantaneous process visibility and drastically simplifies the operation of the equipment.

Components controlled by the HMI include:

- Wiper Speed

- Vacuum Pump

- Extract Pumps

- Feed Skid Mixers

Intelligently Designed, Internal Short-Path Condenser

The WFD-V’s internal stainless steel condenser is a multi-tube design that offers higher condensation performance, larger heat transfer area, greater distillation capacity, and better product quality when compared with common cold finger or spiral condenser designs.

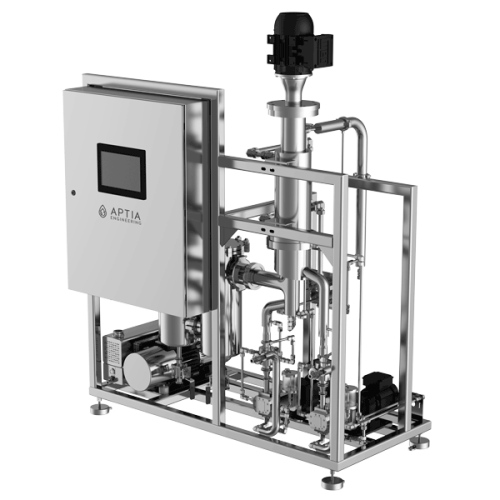

Powerful Vacuum Pumps Optimized for Extract Distillation

A wiped film distillation system is only as good as its vacuum system. There are many different types and models of vacuum pumps, but only a few are suitable for reliable use in extract distillation operations.

Different types of pumps, such as roots blowers, diffusion pumps, and turbomolecular pumps produce their best pumping speeds at different vacuum levels. Pumps from different manufacturers, and even different models of pumps from the same manufacturer, have dramatically different lifespans and maintenance records when put into harsh extract distillation service.

Aptia’s experienced engineers have optimized our vacuum systems to not only provide excellent pumping speeds at the vacuum levels used during extract distillation, but also to provide great longevity and ease of maintenance despite the application being extremely tough on pumps.

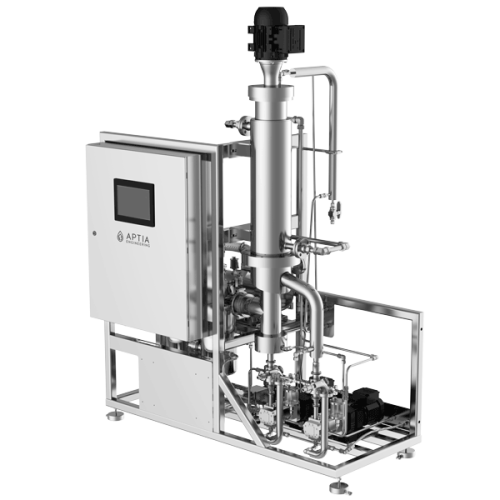

Designed with Quality Components for Longer Uptime & Lower Maintenance

Two-Stage high-Capacity Cold Trap

Aptia’s unique cold trap was designed specifically for extract distillation and captures valuable terpenes much more efficiently than competitive cold traps. Better terpene capture yields deeper vacuum levels, increased throughput, and greatly reduced vacuum pump maintenance.

Heated Gear Pumps

Precision, high-quality gear pumps are used throughout the WFD-V system to allow operators to precisely control the feed rate of extract into distillation, the collection rate of distillate, and the collection rate of residue. Larger systems are equipped with terpene collection pumps to allow for continuous processing.

QUALITY COMPONENTs

High-quality European and domestic components are used throughout the system, including precision gear pumps, industrial gear motors, and high-performance vacuum pumps.

No Corners Cut

Every pipe that conveys extract is jacketed and heated by thermal fluid to eliminate blockages caused by cold extract. This system is designed with integrity and thorough attention to detail. You won’t find heat tape anywhere.

Available Models

WFD-V12

3-5 kg

Hourly Product Throughput*

0.12 m2

Heat Transfer Surface Area

WFD-V36

8-15 kg

Hourly Product Throughput*

0.36 m2

Heat Transfer Surface Area

WFD-V12

3-5 kg

Hourly Product Throughput*

0.12 m2

Heat Transfer Surface Area

WFD-V36

8-15 kg

Hourly Product Throughput*

0.36 m2

Heat Transfer Surface Area

*Actual throughputs may vary based on running parameters

In-depth technical specifications are available upon request.