HCE

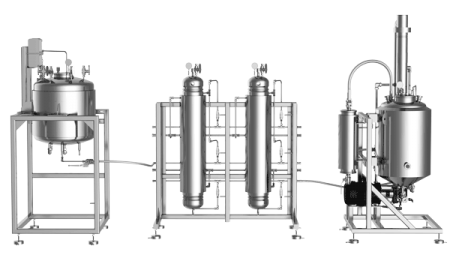

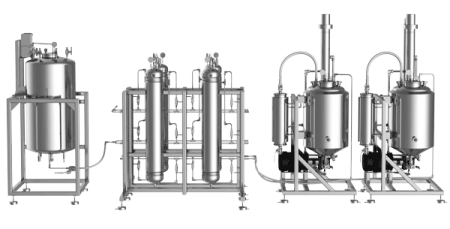

Hydrocarbon Extraction Platform

Aptia’s hydrocarbon extraction systems offer a modular and expandable design with components that can be assembled to meet extraction capacities from 20-160 lbs/hr and which supports extraction temperatures ranging from room temperature down to -112° F / -80° C

Available Models

Applications

One Year Warranty

Installation and Training Support

Engineered & Built in the USA

Thoughtful Design, Massive Efficiency

The HCE lineup of closed loop hydrocarbon extraction equipment offers a modular approach to building high-efficiency extraction systems. These versatile systems can accommodate processors’ individual extraction parameters, such as their desired end product, throughput requirements and local safety regulations.

Modular, expandable designs with a focus on repeatable extract quality, safety and efficiency have become the signature of the HCE hydrocarbon systems. The HCE is available in several standard configurations, and can also support custom configurations.

Key Features

- Industry leading solvent recovery rates

- Automated recovery compressor for superior product quality and consistency

- Hassle free extractor loading and unloading due to innovative side-entry plumbing

- Optimized temperature control equipment for maximum capacity and consistency

- Wide range of operating conditions for efficient manufacturing of sauce, shatter, distillate, and everything in between

- Simple operation and minimal maintenance

Thoroughly Engineered

Every feature and component of the HCE system has been expertly designed to maximize your operational efficiency and profitability.

Beneficial Automation

Proprietary software, a touchscreen HMI, and numerous pressure and temperature sensors provide superior system control. Compressor automation increases product consistency, helps prevent boil over, and protects terpenes while maximizing throughput.

Safety & Compliance

Every system is diligently designed, engineering peer reviewed, and ready for installation in your jurisdiction.

Serious Throughput

Tired of waiting for solvent to recover or cool? Proper thermodynamic analysis and diligent heat transfer engineering enable the Aptia HCE platforms to recover and chill solvent as quickly as you use it. Aptia’s HCE platforms can process many times more botanical material than competitive systems of the same “size,” providing you high extraction rates at competitive equipment prices.

Temperature Configurations

Aptia’s hydrocarbon extraction systems are available in three Temperature Configurations. The valves, hoses, fittings, and vessels are all optimized for each configuration.

Matching your application to the best Temperature Configuration ensures efficient, reliable operation.

Room Temperature

Room Temp

– Unjacketed and Uninsulated

– Regular Temperature Components

Low Temperature

(-40)° F / (-40)° C

– Jacketed and Insulated

– Low Temperature Components

Ultra-Low Temperature

(-112)° F / (-80)° C

– Jacketed and Insulated

– Cryogenic Rated Components

Pre-Configured Models

These standardized systems come with pre-defined solvent storage, extraction, solvent recovery and compressors engineered to meet target extraction rates.

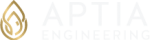

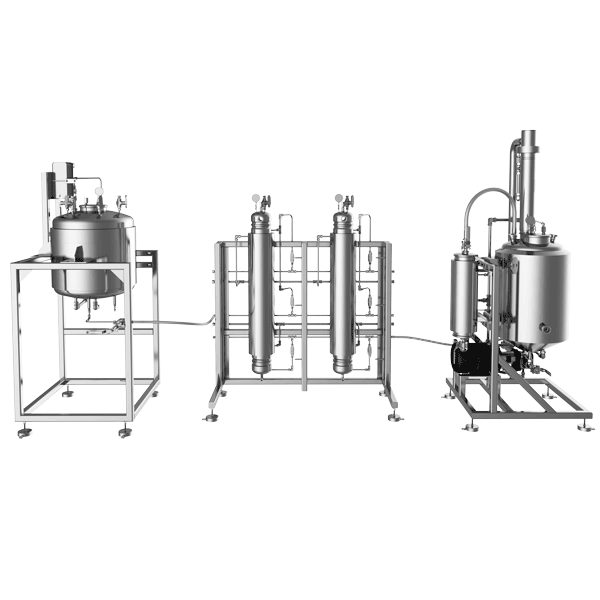

HCE20

HCE20-RT | HCE20-LT

Overview

The HCE20 is an excellent quality entry level hydrocarbon extraction skid. This skid is compact, easy-to-install, energy efficient, and boasts two 10-Liter 6”x24” extractors. The robust recovery system design allows for up to 20 Lbs/Hr of extraction. The HCE20 is only offered in RT and LT Temperature Configurations.

Production

- Extraction Capacity1: 20 Lbs/Hr

- Extractor Volume: 40-Liters

System Includes

- One 40-Liter Solvent Storage Column

- Two 6”x24” 10-Liter Extraction Columns

- One 40-Liter Solvent Recovery Column

- Choice of MVP or Haskel Hydrocarbon Compressors

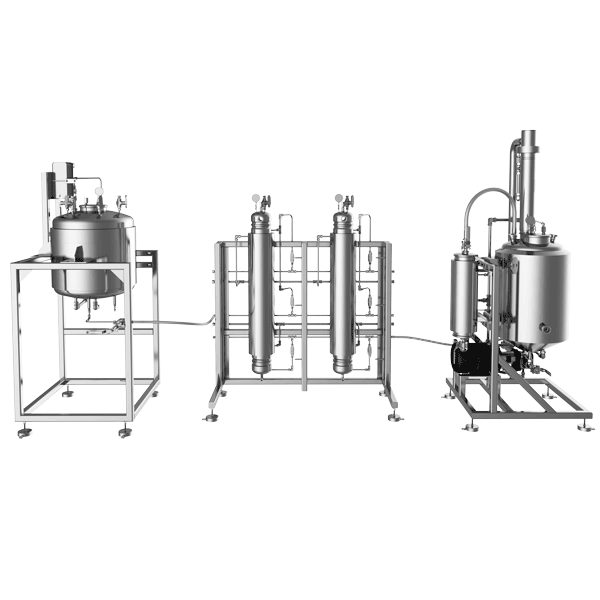

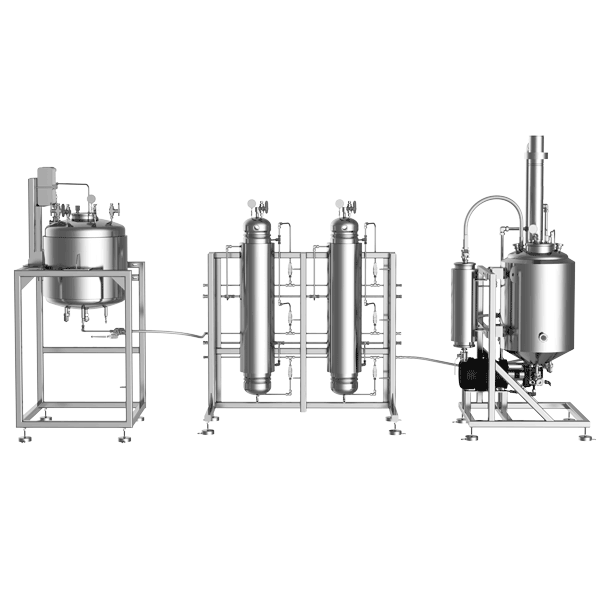

HCE40

HCE40-RT | HCE40-LT | HCE40-ULT

Overview

The HCE40 is the smallest production scale hydrocarbon extraction system that Aptia offers. The unit is built on an expandable, modular platform with separate extraction, recovery, and butane storage skids. This versatile system can be expanded later to more than double its extraction capacity. The HCE40 and all of Aptia’s production scale hydrocarbon extraction systems are offered in ULT, LT, and RT configurations.

Production

- Extraction Capacity1: 40 Lbs/Hr

- Extractor Volume: 40-Liters

System Includes

- One 150-Lb Jacketed ASME Solvent Storage Skid

- One Extraction Skid Equipped with Two 20-Liter 6”x48” Extractors

- One Solvent Recovery Skid Equipped with a 120-Liter High Capacity Recovery Vessel

- One Explosion Proof Electric Gas Compressor with Intuitive HMI Controls

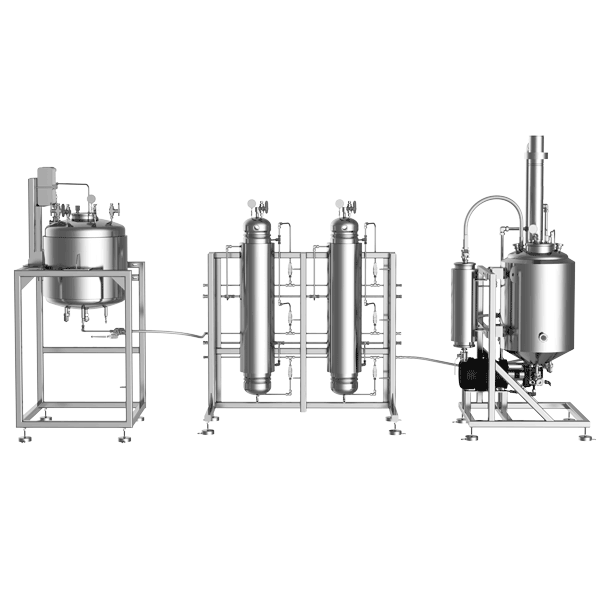

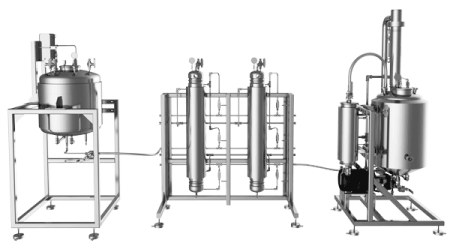

HCE80

HCE80-RT | HCE80-LT | HCE80-ULT

Overview

The HCE80 is a versatile, high throughput extraction system boasting up to 80 Lbs/Hr of extraction capacity. Compact and reliable, the HCE80 is a work horse that can produce extract at an exceptional rate.

Production

- Extraction Capacity1: 80 Lbs/Hr

- Extractor Volume: 80-Liters

System Includes

- One 150-Lb Jacketed ASME Solvent Storage Skid

- One Extraction Skid Equipped with Two 40-Liter 8”x48” Extractors

- One Solvent Recovery Skid Equipped with a 120-Liter High Capacity Recovery Vessel

- One Explosion Proof Electric Gas Compressor with Intuitive HMI Controls

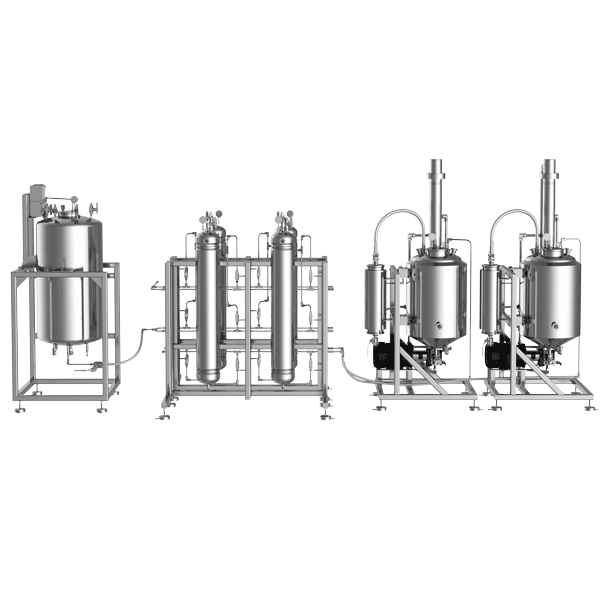

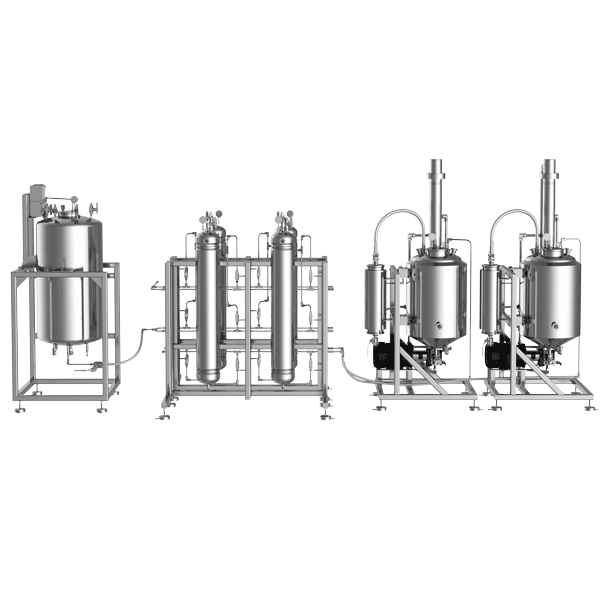

HCE160

HCE160-RT | HCE160-LT | HCE160-ULT

Overview

The HCE160 is designed for businesses that have exceptionally high extraction capacity requirements. The system provides up to 160 Lbs/Hr of extraction capacity and is designed for extreme reliability and 24-Hr/day operation. The HCE160 provides craft quality at an industrial quantity.

Production

- Extraction Capacity1: 160 Lbs/Hr

- Extractor Volume: 160-Liters

System Includes

- One 300-Lb Jacketed ASME Solvent Storage Skid

- Two Extraction Skids, Each Equipped with Two 40-Liter 8”x 48” Extractors

- Twin Recovery Skids, Each Equipped with a 120 Liter Evaporator

- One Explosion Proof Gas Compressor with Intuitive HMI Controls

1 Estimated extraction capacities are based on the assumptions that two extractions per hour are conducted in each extraction column, and that the botanical material is packed into the extractors at a density of 0.5 Lbs/Liter.

Custom Configurations

Don’t see the right pre-configured model for your process? Configure the perfect hydrocarbon extraction system for your business by developing a custom configuration with a process engineer at Aptia.

Aptia’s process engineers can help you optimize your extractor for large, small, hot, cold, or specialty processes.