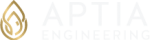

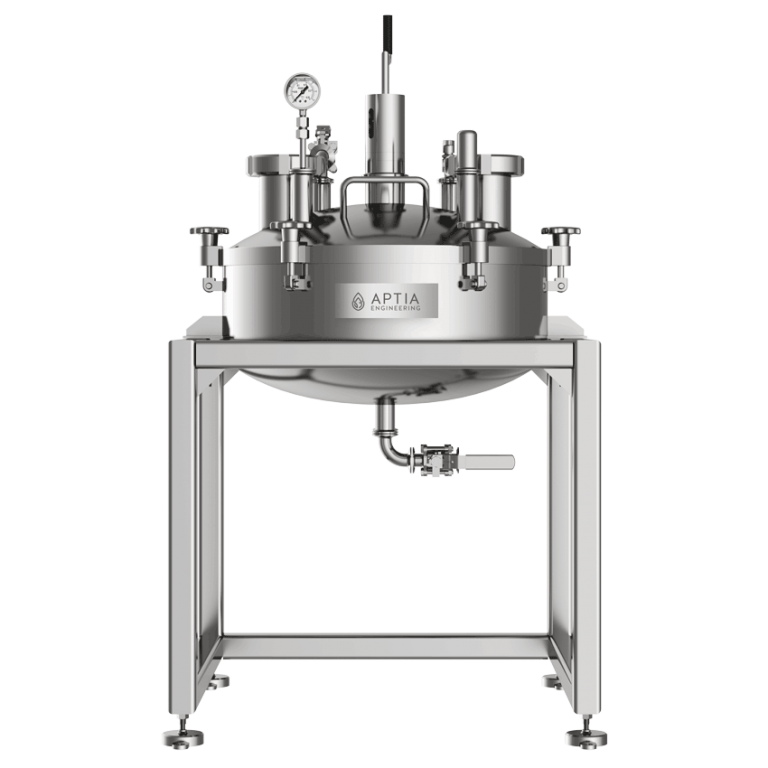

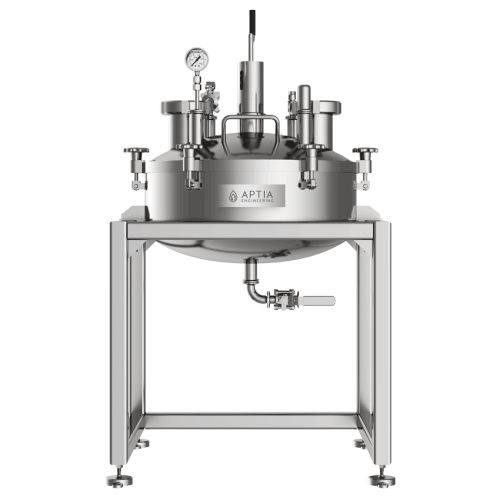

DWF

Pressure-Rated Winterization Filter

The Buchner Filter, evolved. The DWF is a sealed, pressure-rated, high capacity stainless steel filtration system that speeds up a variety of hemp extract refining processes.

Available Models

Primary Applications

One Year Warranty

Installation and Training Support

Engineered & Built in the USA

Product Description

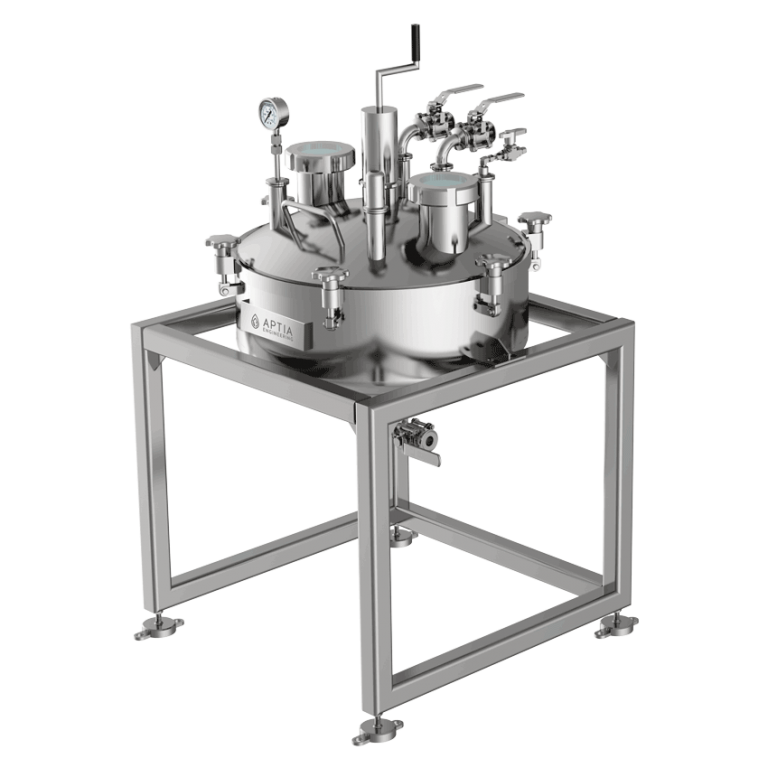

The DWF is a high capacity, completely sealed, stainless steel filtration system that speeds up a variety of hemp extract refining processes. It excels at filtering out fats/waxes during winterization, and also at separating CBD isolate from mother liquor during crystallization processes. When used for dewaxing, the DWF can be equipped with a wax layer agitation system that increases the filtration rate by helping prevent the wax from plugging up the filter. Additionally, the DWF can be used for color remediation processes by acting as a housing for large quantities of adsorbents such as activated carbon, bleaching clays, or diatomaceous earth.

The DWF’s completely sealed housing ensures protection from flammable solvent vapors, is easy-to-clean, and provides high throughput filtration. The DWF provides an excellent filtration solution for common hemp processing steps.

Features

- Sealed design reduces open-air handling of flammable solvents and reduces the risks of product contamination or spillage

- Innovative housing design is easy to clean and fast to swap between filtrations

- Optional wax agitator allows for better filtration rates during winterization

- High surface area delivers rapid filtration rates

- Sealed housing design can be filled with activated carbon, bleaching clays or other adsorbents

- Robust stainless housing can be used with positive pressure or vacuum to accelerate filtration

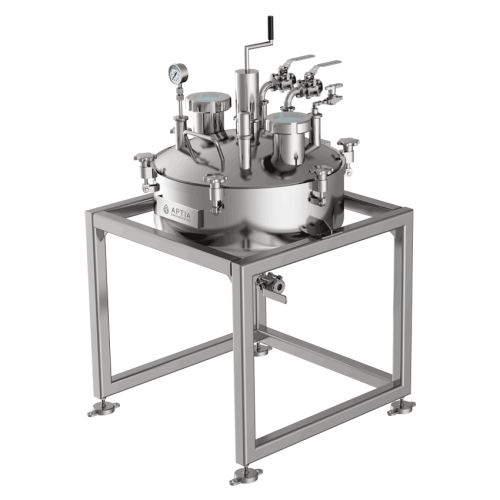

Specifications

Material of Manufacture

Stainless Steel

Filtration Surface Area

20″ Diameter

System Min/Max Temperature

-40° C / 50° C

System Min/Max Pressure

Full Vacuum / 15 PSIG

Suggested Ancillary Equipment

Winterization Reactors such as R15, R35 or R60, temperature control units, and vacuum pumps

System Dimensions

28″ L x 28″ W x 40″ H

System Weight

~150 Lbs

Compatible Solvents

Gasket kits available for use with ethanol, methanol, IPA, hexane or heptane*

*Application specifics must be reviewed and approved by Aptia at time of purchase to ensure system compliance and safety with intended use

The Benefits of Completely Sealed Filtration

The sealed housing has numerous advantages over standard buchner funnels.

Use Positive Pressure & Vacuum

Prevent Product Contamination

Sealed filtration prevents contamination of product by airborne contaminants such as mold spores, and helps processors achieve the GMP certification that will make their business successful in the long run.

Contain Flammable Vapors

Designed for Efficiency & Ease of Operation

With its huge circular filtration area of 20 inches in diameter, the DWF offers high filtration throughput. The system is pressure rated to allow operators to apply positive pressure or vacuum to further simplify equipment setup and allow for faster processing.

The easy-access housing design and full-width manway allow for the filtration media to be easily and quickly changed. Processes can be monitored through various sight glasses installed throughout the system.

Compatible With a Range of Filtration Mediums

Key to the DWF’s versatility is its ability to function optimally with a large variety of filtration media.

Depth filtration sheets, paper sheets, cloth filters, stainless mesh filters, and other flat media can be used inside the DWF. Processors can load filtration media as course as 250 micron, or as fine as 0.5 micron into the filter. Stainless media can often be re-used, and flat filtration media is the most economical type of filtration media to replace.

For those seeking to perform color remediation or other processes, the DWF acts as housing for large quantities of adsorbents such as activated carbon, bleaching clays, or diatomaceous earth.