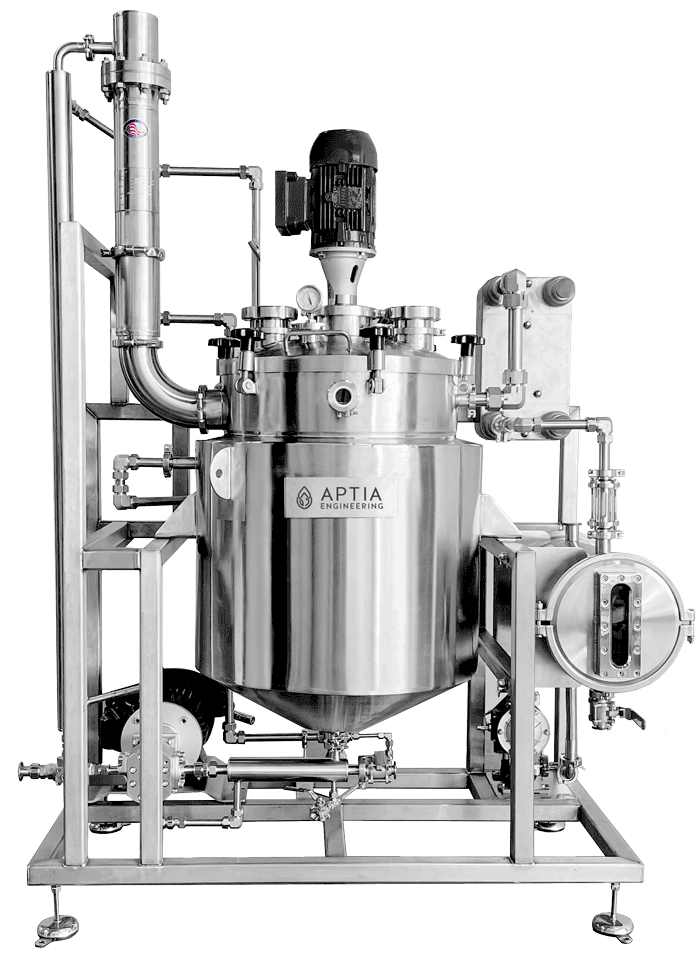

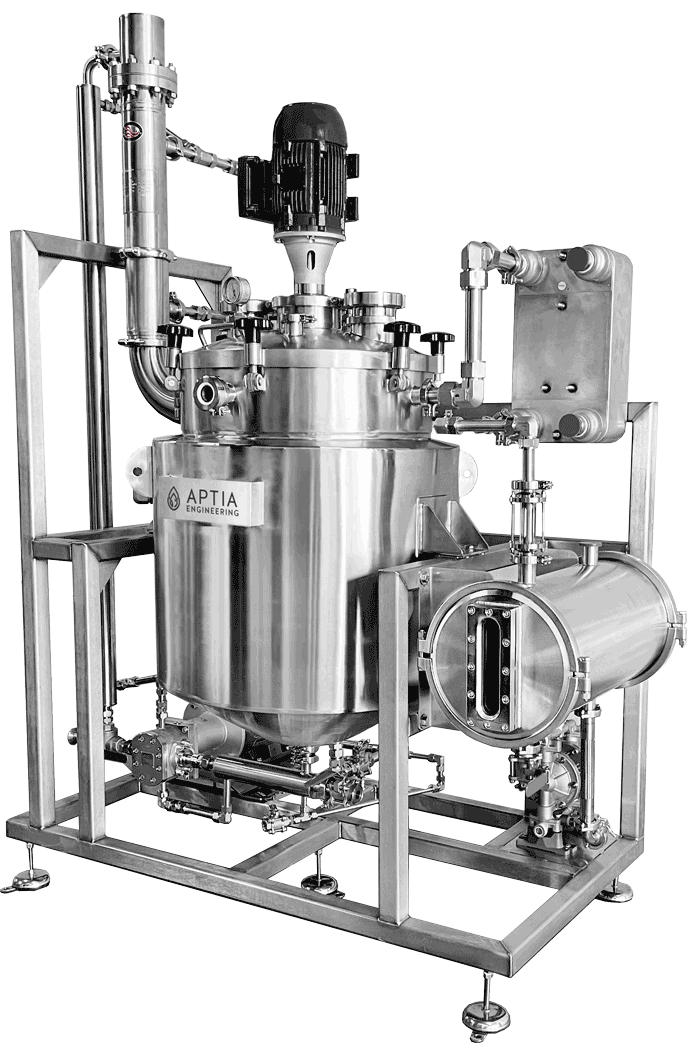

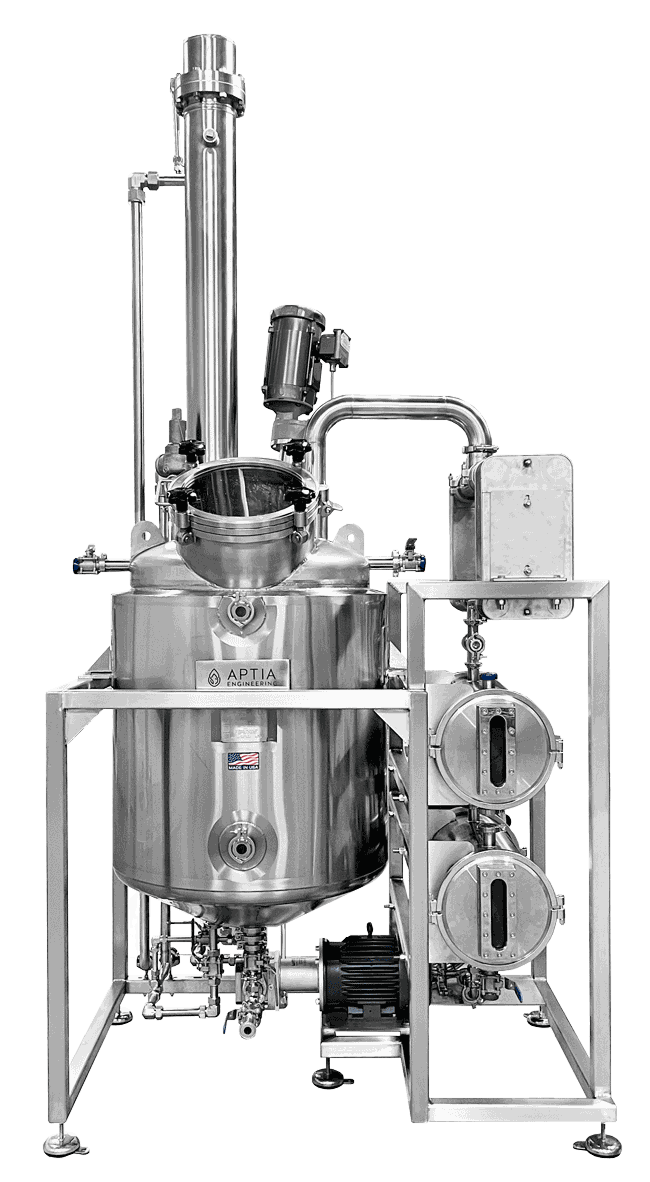

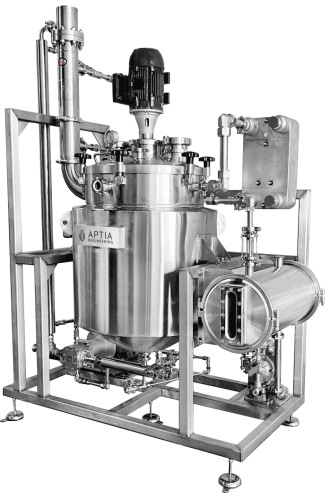

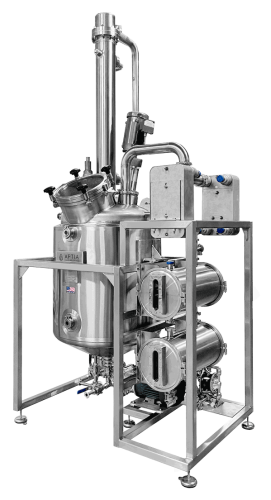

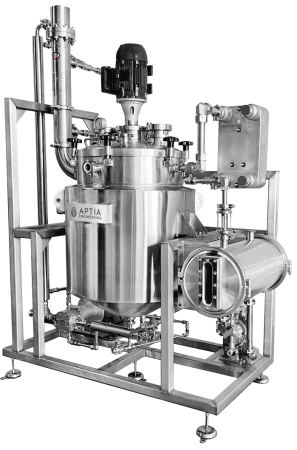

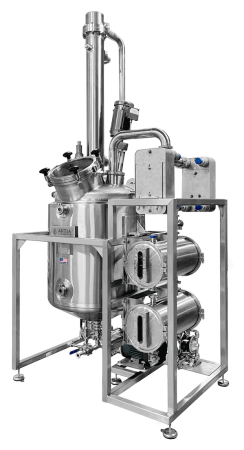

Expanding on Aptia’s versatile RX reactor platform, the RX-FFE is a robust and complete solvent recovery solution for hemp processors. The RX-FFE reduces the total amount of equipment required to produce extract by allowing operators to perform three critical post-extraction steps in one compact system: primary solvent recovery, residual solvent stripping, and decarboxylation.

By strategically integrating falling film solvent recovery technology with a full-vacuum rated reactor, the RX-FFE can provide fast solvent recovery, residual solvent stripping, and decarboxylation capabilities. The system is versatile, and the operator can choose which process or processes he or she wishes to conduct.

The core of the RX-FFE is the RX reactor from Aptia’s Multipurpose Reactor Series. The operator can elect to use only the RX portion of the equipment to accomplish other reactor processes such as bulk winterization, crystallization, batch blending, or flavoring. These additional capabilities can be very helpful in the hemp facility that wishes to invest in the minimal amount of equipment, or in the facility that is limited in total floor space. Please let Aptia know if performing these additional processes will be important to you, and an Aptia engineer will help select the best temperature control equipment for your purpose.